Stretch Lace plays an important role in fashion design. It can not only add more charm and fashion sense to women's clothing, but also reflect the exquisite craftsmanship and designer's taste. Of course, due to the special nature of the elastic lace fabric, it also requires some precautions in use and maintenance. Here are some tips for using and caring for stretch lace fabrics:

Avoid over-stretching: Although stretch lace fabric has certain elasticity and resilience, over-stretching will cause the fabric to deform and affect the appearance and quality of the garment.

Gentle wash: Stretch lace fabric should be washed with a mild detergent, preferably by hand. Avoid using bleach and hot water as they can damage the fabric.

Drying method: Elastic Lace Fabric should avoid direct exposure and high temperature drying, it is best to choose a cool and ventilated place to dry or dry at low temperature.

Storage method: When storing elastic lace fabrics, you should avoid placing them in the sun or in a humid environment for a long time to prevent the fabric from becoming moldy or deformed.

To sum up, elastic lace fabric is a very important fashion fabric. It not only has high technical requirements in design and production, but also requires special use and maintenance methods to ensure the quality and life of clothing. We also have Eyelash Lace, if you need it, you can contact us.

Product Ingredients:

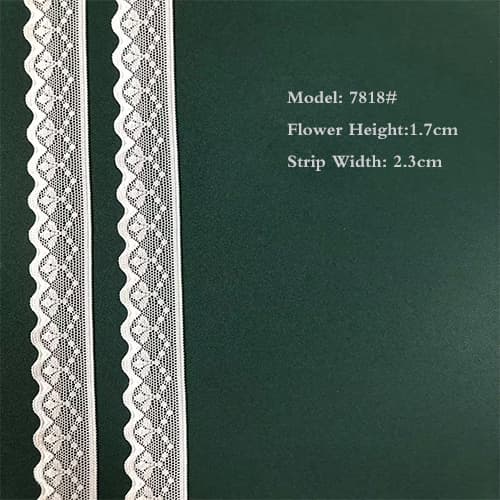

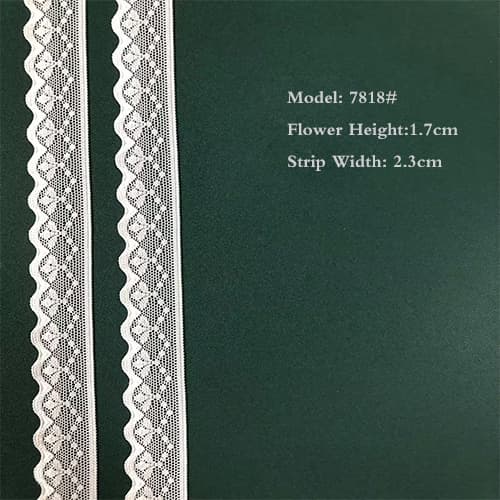

Flower Height: 1.7cm

Strip Width:2.3cm

Product Display

When selecting the best fabric for your needs, several key characteristics must be considered to ensure optimal performance, comfort, and durability. Below are four to six critical features, backed by professional data, to guide your decision-making process.

1. Breathability (Air Permeability): High-quality fabrics allow air circulation, reducing heat buildup. For instance, cotton has an air permeability of 60-100 cm³/cm²/sec, while polyester ranges from 10-30 cm³/cm²/sec. Natural fibers like linen excel with values exceeding 120 cm³/cm²/sec, making them ideal for warm climates.

2. Moisture-Wicking: Fabrics like merino wool can absorb up to 30% of their weight in moisture without feeling damp, while synthetic blends (e.g., nylon-spandex) offer rapid evaporation rates of 0.2-0.4 mL/min, ensuring dryness during physical activity.

3. Tensile Strength: Durability is measured in megapascals (MPa). Denim averages 20-30 MPa, whereas high-performance fabrics like Kevlar® reach 3,000 MPa, resisting tearing under stress.

4. Thermal Insulation: Measured in clo units (1 clo = 0.155 m²·°C/W), down feathers provide 0.7-0.9 clo, while fleece offers 0.2-0.4 clo, balancing warmth and weight.

5. UV Protection (UPF Rating): Tightly woven fabrics like polyester-cotton blends achieve UPF 30-50, blocking 96-98% of UV rays. Specialty fabrics with coatings can exceed UPF 50+.

6. Pilling Resistance: Measured on a scale of 1-5 (5 being best), wool scores 3-4, while microfiber polyester achieves 4-5 due to its smooth fiber structure.

By evaluating these scientifically validated metrics, you can select fabrics tailored to specific requirements, whether for athletic wear, outdoor gear, or everyday comfort. Prioritizing data-driven attributes ensures long-term satisfaction and performance.

1. Fashion & Apparel

The best fabrics elevate fashion design by combining aesthetics with functionality. Premium materials like silk, cashmere, and organic cotton dominate luxury clothing lines, offering unparalleled comfort and durability. Technical fabrics with moisture-wicking or UV-protection properties are revolutionizing activewear and outdoor apparel.

2. Home Textiles

From Egyptian cotton bed linens to stain-resistant microfiber upholstery, superior fabrics transform living spaces. High-performance textiles with thermal regulation create ideal bedroom environments, while flame-retardant fabrics ensure safety in curtains and furniture coverings.

3. Medical Applications

Advanced antimicrobial fabrics are critical in healthcare settings for wound dressings, surgical gowns, and bedding. Smart textiles with embedded sensors monitor patient vitals, while breathable, hypoallergenic materials improve comfort for long-term care patients.

4. Automotive Industry

Automotive interiors demand durable, easy-to-clean fabrics that withstand UV exposure and heavy use. Premium vehicles incorporate sound-absorbing textiles and temperature-regulating seat fabrics, while eco-friendly materials like recycled polyester gain popularity.

5. Technical Protective Gear

Fire-resistant aramid fibers protect firefighters, while cut-resistant fabrics safeguard industrial workers. Military applications utilize camouflage fabrics with infrared-defeating properties, and space programs rely on specialized temperature-resistant textiles.

6. Sustainable Architecture

Architectural fabrics enable innovative tensile structures for stadiums and pavilions. PTFE-coated fiberglass membranes provide weather resistance, while photovoltaic textiles integrate solar cells into building facades, merging functionality with energy efficiency.