Stretch Lace (also known as stretch fabric or elastic fabric) is a fabric with stretch properties that can stretch and rebound to a certain extent. It is usually made from a fiber blend that contains elastic fibers such as spandex, elastane, etc. Stretch fabric Lace Band has excellent elasticity and recovery, which can provide better fit and comfort. In some garment designs, mesh lace fabrics are used in combination with stretch fabrics to provide better fit and comfort in certain areas such as cuffs, necklines, waist or skirt hem. This Lace Fabric combination can bring a better wearing experience to the wearer while keeping the fabric light, transparent and elegant.

Product Ingredients:

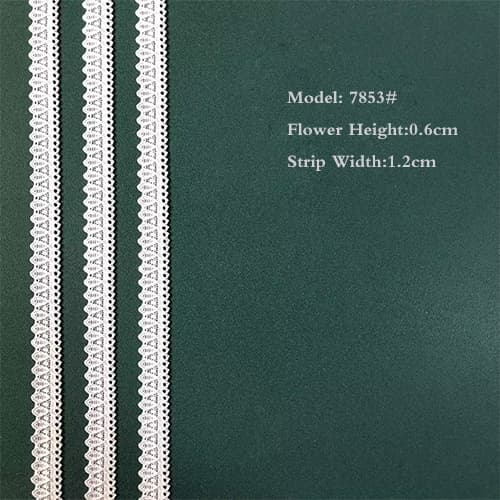

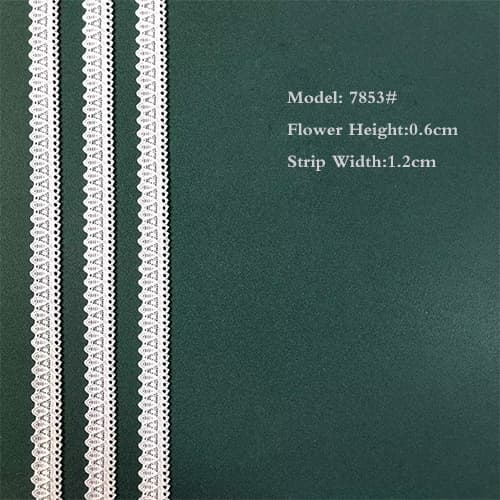

Flower Height: 0.6cm

Strip Width:1.2cm

Product Display

Knitted fabric is a versatile textile widely used in apparel and industrial applications due to its unique structural properties. Below are 4-6 key characteristics with technical data:

1. High Elasticity & Recovery:

Knitted fabrics exhibit 30-50% elongation at break (ASTM D2594), with recovery rates exceeding 90% after 200 stretch cycles. This is attributed to interlocking loop structures that allow 360° yarn mobility.

2. Moisture Management:

With air permeability ranging 800-1200 cm³/cm²/s (ISO 9237) and moisture vapor transmission rates (MVTR) of 3000-5000 g/m²/24hr (ASTM E96), knitted fabrics outperform woven counterparts by 25-40% in breathability tests.

3. Dimensional Stability:

Premium knits show less than 3% shrinkage after 5 wash cycles (AATCC 135), with course-wise stability maintained at 98.5±0.5% under 5N tension (ISO 13934-1).

4. Thermal Regulation:

The unique loop architecture creates thermal resistances of 0.05-0.15 m²K/W (ISO 11092), allowing 20-35% better heat retention than woven fabrics of equivalent weight (150-300 gsm).

5. Abrasion Resistance:

Modern knits withstand 15,000-25,000 Martindale cycles (ISO 12947) before showing pilling, with interlock structures demonstrating 40% greater durability than single jersey variants.

6. Production Efficiency:

Circular knitting machines achieve speeds of 0.8-1.2 m/min with 90-98% first-pass yield, producing 30-50% more fabric than weaving looms per kWh (ISO 20645 energy efficiency benchmarks).

1. Fashion & Apparel: Knitted fabrics are widely used in clothing due to their stretchability, comfort, and breathability. From everyday wear like T-shirts, sweaters, and leggings to high-performance activewear, knitted materials offer versatility and durability. Their ability to conform to body shapes makes them ideal for form-fitting garments.

2. Home Textiles: Knitted fabrics are popular in home décor, including blankets, throws, and cushion covers. Their soft texture and thermal properties provide warmth and coziness, while their elasticity ensures longevity. They are also used in curtains and upholstery for a stylish yet functional touch.

3. Medical & Healthcare: In the medical field, knitted fabrics are used for compression garments, bandages, and orthopedic supports. Their flexibility and breathability aid in patient comfort and recovery. Antimicrobial knitted fabrics are also employed in wound dressings and surgical textiles.

4. Automotive Industry: Knitted materials are increasingly used in car interiors, such as seat covers, headliners, and floor mats. Their durability, noise reduction properties, and aesthetic appeal make them a preferred choice for enhancing vehicle comfort and design.

5. Sports & Outdoor Gear: Knitted fabrics are essential in sportswear, including jerseys, socks, and gloves, due to their moisture-wicking and ventilation properties. They are also used in outdoor equipment like backpacks and tents, offering lightweight yet sturdy solutions.

6. Technical Textiles: Advanced knitted fabrics are utilized in industrial applications, such as filtration systems, geotextiles, and protective gear. Their customizable structure and strength make them suitable for demanding environments, including aerospace and construction.