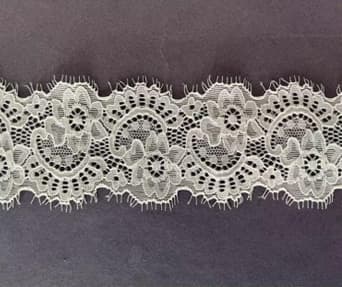

Elastic Lace Bands represent a harmonious blend of functionality and aesthetic appeal, gracing a multitude of fashion applications. In this article, we delve into the intricate world of manufacturing these bands, exploring the meticulous processes and thoughtful material selections that contribute to their versatility and allure.

1.Material Selection:

At the heart of Elastic Lace Bands lies a careful consideration of materials. The selection process involves choosing from a range of elastic fibers, such as spandex or lycra, known for their exceptional stretch and recovery properties. Additionally, materials like nylon and polyester are often incorporated for durability, ensuring the bands withstand regular use while maintaining their form.

2.Thread Choices:

The manufacturing process involves selecting threads that enhance both the strength and delicacy of the lace. High-quality threads, often made of polyester or a blend of synthetic fibers, contribute to the intricate patterns and provide structural integrity to the bands.

3.Dyeing Techniques:

The color palette of Elastic Lace Bands is a crucial aspect of their allure. Manufacturers employ various dyeing techniques, including vat dyeing or continuous dyeing methods, to achieve vibrant and consistent colors. This attention to detail ensures that the bands seamlessly integrate into diverse fashion applications.

4.Jacquard Weaving:

The hallmark of Elastic Lace Bands is their captivating patterns, often achieved through Jacquard weaving. This intricate weaving technique involves a specialized loom, allowing for the creation of detailed and complex lace designs. The precision of Jacquard weaving contributes to the bands' elegance and adds a touch of sophistication to the final product.

5.Cutting and Shaping:

Following the weaving process, the Lace fabric undergoes precision cutting to form the desired width and length of the bands. Advanced cutting technologies, such as laser cutting, ensure clean edges and intricate details, allowing for customization based on design requirements.

6.Bonding Techniques:

Elastic Lace Bands often require bonding to enhance their functionality. Manufacturers employ bonding techniques, including ultrasonic bonding or adhesive bonding, to create seamless joints and prevent fraying. This ensures the bands maintain their structural integrity even under stress.

7.Quality Control Measures:

Throughout the manufacturing process, rigorous quality control measures are implemented. Inspections are conducted at various stages, from material sourcing to the final product, to ensure that each Elastic Lace Band meets stringent quality standards. This commitment to quality is essential for delivering products that exceed customer expectations.

8.Stretch and Recovery Testing:

Given the elastic nature of these bands, stretch and recovery testing is a crucial step. Manufacturers employ specialized equipment to assess the bands' ability to stretch and return to their original shape. This testing ensures that the bands maintain their elasticity and snug fit over time.

9.Finishing Touches:

The final steps involve adding finishing touches to enhance the aesthetic appeal and comfort of Elastic Lace Bands. Softening treatments, antimicrobial finishes, or moisture-wicking technologies may be applied to elevate the bands' overall quality and wearability.

10.Sustainability Initiatives:

In response to growing environmental concerns, manufacturers are increasingly adopting sustainable practices. This includes exploring eco-friendly materials, implementing water-saving dyeing processes, and minimizing waste during production to align Elastic Lace Band manufacturing with sustainable fashion practices.

Crafting Elastic Lace Bands involves a meticulous blend of material selection, weaving techniques, precision cutting, and quality control measures. The result is not merely a functional accessory but a delicate and elegant embellishment that finds its place in diverse fashion applications. As technology advances and sustainability takes center stage, the manufacturing of Elastic Lace Bands continues to evolve, offering both aesthetic beauty and conscientious craftsmanship.